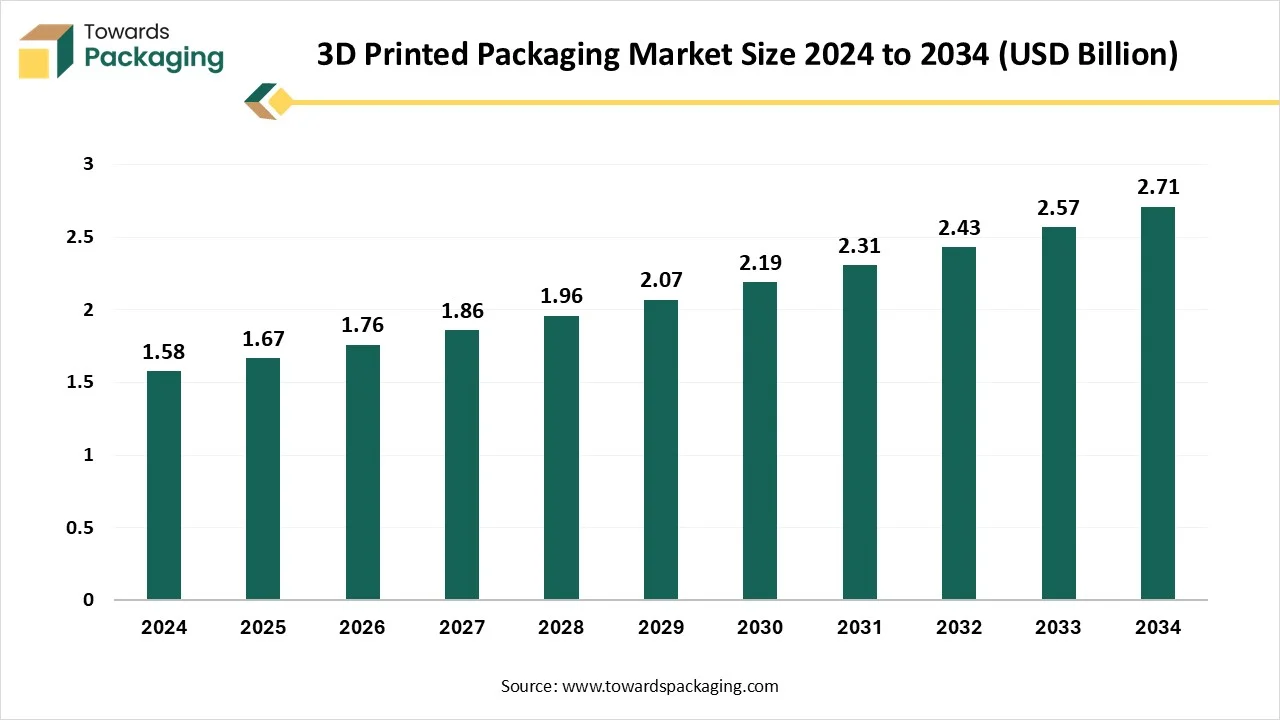

3D Printed Packaging Market Worth USD 2.71 Bn by 2034

According to a recent analysis by Towards Packaging, the global 3D printed packaging market is projected to expand from USD 1.76 billion in 2026 to USD 2.71 billion by 2034, recording a CAGR of 5.53% between 2025 and 2034.

Ottawa, Sept. 29, 2025 (GLOBE NEWSWIRE) -- The global 3D printed packaging market size was recorded at USD 1.67 billion in 2025 and is forecast to increase to USD 2.71 billion in 2034, as per findings from a study published by Towards Packaging, a sister firm of Precedence Research.

Key trends in the market include a growing demand for sustainable and eco-friendly packaging materials, the advancement of AI-based design software to create complex and customized packaging solutions, and the increasing use of 3D printing for end-use manufacturing beyond prototyping.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5680

What is Meant by 3D Printed Packaging?

3D printed packaging utilizes additive manufacturing to create custom, complex packaging designs from digital models, allowing for rapid prototyping, tailored functionality, unique aesthetics, and the use of sustainable materials. This expansion is driven by the increasing need for customized, sustainable packaging, developments in additive manufacturing technology, and the flexibility that 3D printing provides for creating unique packaging solutions, as well as functional packaging like self-stirring cups.

What are the Latest Trends in the 3D Printed Packaging Market?

-

Shift from Prototyping to Full-Scale Production Using Advanced Materials

This trend is driven by enhancements in speed, cost-effectiveness, and material capabilities, allowing for mass customization and efficient, on-demand manufacturing of diverse geometries and small-to-medium runs. 3D printing enables a seamless transition from design to product, reducing expenses and the need for time-consuming redesigns. By eliminating the need for expensive molds and tooling, 3D printing reduces costs, particularly for short runs and customized products.

-

Rapid Prototyping & Tooling Advancements

3D printing is increasingly used to produce molds, trays, and prototype packaging designs within hours, rather than weeks, significantly reducing tooling expenses. This acceleration in the design process not only shortens time-to-market but also allows for quicker iterations and reduced risk in final product development.

What Potentiates the Growth of the 3D Printed Packaging Market?

-

Demand for Sustainable and Personalized Packaging

Consumers have become increasingly aware of the environmental impact of packaging waste and are actively seeking brands that offer sustainable, eco-friendly, and recyclable packaging options. Custom designs, textures, and even logos created via 3D printing can significantly enhance the overall customer experience, contributing to raised engagement and brand loyalty. 3D printing's ability to create intricate and bespoke packaging solutions is particularly valuable for luxury goods, cosmetics, and specialty food products, catering to users seeking unique and premium experiences.

-

Advancements in AI-driven Design Software and Multi-Material Printing

AI algorithms determine customer information and preferences to create tailored packaging designs on demand, meeting specific user requirements and preferences. Generative design tools utilize AI to create complex geometries that enhance strength, reduce weight, and optimize material usage, contributing to more efficient and innovative packaging solutions. AI enables the creation of sophisticated and multifunctional packaging, along with multi-material printing, supporting innovation and potentially leading to more sustainable packaging solutions.

If there is anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

What are the Limitations & Challenges in the 3D Printed Packaging Market?

There is a limited range of 3D printable materials that are both food-safe and durable, and also meet specific performance demands for packaging, such as high heat deflection temperatures and thus strength. Even with advancements, the expense of innovative and sustainable materials suitable for 3D printing typically remains higher than that of conventional options, making them less economically viable in cost-sensitive markets. Achieving desired surface finishes, strength, and aesthetic standards typically requires extensive and labor-intensive post-processing, which can increase complexity and cost.

More Insights of Towards Packaging:

- 3D-Printed Stickers & Labels Market Drives at 7.3% CAGR (2025-34) - The 3D-printed stickers and labels market is expected to increase from USD 965.7 million in 2025 to USD 1820.71 million by 2034.

- Print-receptive PE films Market Key Trends, Disruptions and Strategic Imperatives - The print-receptive PE films market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- Packaging Tape Printing Market Drives at 7.58% CAGR (2025-34) - The packaging tape printing market is expected to increase from USD 41.56 billion in 2025 to USD 80.21 billion by 2034.

- North America Packaging Tape Printing Market Leadership in 2025 Reinforced by 3M, Shurtape, and UPM New Product Launches - The North America packaging tape printing market is predicted to expand from USD 19.13 billion in 2025 to USD 29.78 billion by 2034.

- Folding Carton in Healthcare Market Insights for 2025 Indicate Offset Printing Leadership and Digital Surge - The folding carton in healthcare market is expected to increase from USD 3.75 billion in 2025 to USD 7.05 billion by 2034.

- Plain Packaging Market Trends 2025: Offset Printing, Paperboard Materials, and Regulatory Packaging Lead the Way - The plain packaging market is forecast to grow from USD 5.54 billion in 2025 to USD 11.69 billion by 2034, driven by a CAGR of 8.65% from 2025 to 2034.

- Barrier Coated Flexible Paper Packaging Market Outlook 2025 to 2034: Innovation in Bio-Based Coatings & Digital Printing - The barrier-coated flexible paper packaging market is forecast to grow from USD 18.21 billion in 2025 to USD 30.37 billion by 2034.

- Commercial Printing Market Drives at 5.25% CAGR (2025-34) - The commercial printing market is forecast to grow from USD 531.51 billion in 2025 to USD 842.39 billion by 2034, driven by a CAGR of 5.25% from 2025 to 2034.

- Paper-Based Sustainable Packaging Market Trends 2025: Molded Fiber, Flexographic Printing, and B2C Channels Rising - The paper-based sustainable packaging market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- Low-Carbon Footprint Packaging Market to Witness Rapid Growth Through 2034 with Asia Pacific Leading Innovation in Bioplastics - The low-carbon footprint packaging market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- Offset Printing Market 2025 Research Shows High Growth at 14.13% CAGR to 2034 - The global offset printing market is anticipated to grow from USD 3.48 billion in 2025 to USD 11.38 billion by 2034, with a compound annual growth rate (CAGR) of 14.13%.

- Cardboard Boxes Market to Soar with Fit-to-Product & Digital Printing Innovations - The cardboard boxes market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- Thermal Printing Market 2025 Outlook: Barcode Printers & Direct Thermal Tech to Dominate USD 79.33 Billion Sector - The thermal printing market is projected to reach USD 79.33 billion by 2034, growing from USD 53.70 billion in 2025.

- Digital Textile Printing Market Research, Consumer Behavior, Demand and Forecast - The global digital textile printing market was valued at USD 6.77 billion in 2025, is expected to reach approximately USD 19.92 billion by 2034.

-

Tablet Inspection and Printing System Market Investment Opportunities & Competitive Benchmarking - The tablet inspection and printing system market is anticipated to grow from USD 911.33 million in 2025 to USD 1894.39 million by 2034.

Regional Analysis

Who is the Leader in the 3D Printed Packaging Market?

North America registered dominance in the 3D printed packaging market in 2024. This is due to its strong technological base, a solid ecosystem of major industry players, and significant investment in research and development, which drives innovation in customized and sustainable packaging. The presence of major firms and well-established R&D activities creates a fertile ground for developing 3D printing for packaging applications.

Government initiatives and increased corporate spending on advanced manufacturing technologies, including 3D printing, also contributed to regional dominance. The region’s mature additive manufacturing ecosystem and strong innovation in packaging design are expected to ensure the long-term growth of the market.

U.S. Market Trends

The U.S. is a major contributor to the North America 3D printed packaging market due to the increased need for customization, sustainability, and fast prototyping. Firms are using 3D printing to manufacture personalized packaging for users and also complex designs for specialty items. There is a strong emphasis on reducing packaging waste, utilizing recycled materials, and creating energy-efficient packaging solutions, which contribute to market growth.

Canada Market Trends

There is a growing need for customized packaging solutions, which is a significant contributor to the adoption of 3D printing. Manufacturers are implementing 3D printing into their manufacturing workflows. For instance, Unilever is using Formlabs resin 3D printing to create molds for plastic bottles, significantly reducing mold production time.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

How is the Opportunistic Rise of Europe in the 3D Printed Packaging Market?

Europe is strategically positioned for an opportunistic rise in the market due to consumer demand for customization, brand differentiation, and sustainability. 3D printing enables brands to create innovative and interactive packaging, giving them a competitive edge in the European market by engaging consumers with unique designs and limited-edition items.

Strong collaborations between research institutions and firms, along with strategic alliances among major players, speed up the development of advanced 3D printing solutions for packaging. Brands are leveraging 3D printing to manufacture limited-edition and customized packaging that meets specific user needs for personalized products.

UK Market Trends

The UK 3D printed packaging market is expected to grow significantly, driven by demand for customization and personalization, which 3D printing permits, along with sustainability efforts. The growing adoption of technology across key sectors, such as food & beverages, pharmaceuticals, and cosmetics, is also driving market growth.

France Market Trends

The 3D printed packaging market in France is a niche but growing segment within the broader additive manufacturing landscape, driven by the need for customization, rapid prototyping, and sustainable solutions, primarily in sectors such as consumer goods, healthcare, and food and beverage.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

What Opportunities Exist in Asia Pacific?

The market in Asia Pacific is expected to grow at a significant rate during the forecast period. There is a growing concern about packaging waste, which is driving a need for eco-friendly and innovative packaging solutions. 3D printing helps reduce material waste through on-demand production. Governments in countries such as China and Japan actively support and encourage 3D printing technologies, even lowering entry barriers for businesses, along with fostering greater market penetration.

China Market Trends

The Chinese 3D printed packaging market is poised for remarkable growth, driven by the need for customized products, innovation in materials such as bio-based plastics, and even government investment in high-tech manufacturing. The rising demand for customized packaging solutions across various industries is likely to support market growth.

India Market Trends

The Indian 3D printed packaging market is poised for significant expansion, driven by the growing adoption of additive manufacturing for rapid prototyping, customization, and sustainable solutions across various sectors, including e-commerce, healthcare, and food & beverage. With the rapid expansion of the consumer goods and e-commerce sectors, there is a high demand for recyclable packaging solutions, which is expected to drive market growth.

Segment Outlook

Material Insights

The plastics segment dominated the 3D printed packaging market in 2024 due to their durability, versatility, lightweight nature, and even affordability, along with the ease of producing complex designs and customized solutions efficiently. Plastic materials are generally more affordable and readily available compared to other materials, such as metals, which helps lower production expenses for packaging prototypes and small-scale runs. The development and use of biodegradable and recycled plastics are rising, addressing consumer and regulatory needs for more sustainable packaging solutions and aligning with circular economy principles.

The paper & paperboard segment is expected to grow at the fastest rate during the forecast period. The segment growth is attributed to the growth in e-commerce, regulations against single-use plastics, and rising consumer choice for eco-friendly alternatives. Paperboard also offers superior printability and structural strength for custom packaging, particularly for food and beverages, cosmetics, and personal care products. Governments and industries are increasingly restricting or banning single-use plastics, creating opportunities for paper and paperboard. The expansion in e-commerce and shipping needs durable, recyclable, and even customizable packaging, which paperboard can offer.

Technology Insights

The stereolithography (SLA) segment led the market in 2024 due to its ability to offer highly detailed, complex, and aesthetically pleasing packaging prototypes, as well as end-use sections with smooth surface finishes. Advancements in stereolithography resin formulations have led to enhanced properties, including increased durability and flexibility.

The technology's high resolution, combined with accuracy, makes it ideal for intricate packaging designs. The expanding array of resin materials available for stereolithography printers offers diverse properties, including high strength, biocompatibility, temperature resistance, and flexibility, which enable a broad range of packaging applications.

End-Use Industry Insights

The food & beverages segment dominated the 3D printed packaging market in 2024. 3D printing offers faster, cost-effective, and even flexible solutions for custom designs and prototypes, which are crucial for creating attractive packaging that meets both aesthetic and functional requirements, ultimately helping brands connect with consumers.

Food and beverage brands utilize 3D printing to rapidly offer design variations, test prototypes, and accelerate the overall packaging development process, which is an expense and time-consuming traditional endeavor. 3D printing is utilized to create custom safety features, ergonomic aids, and customized tools for machinery on food production lines, thereby enhancing operator safety and operational efficiency in breweries and select food processing facilities.

The pharmaceutical segment is likely to grow at the fastest rate in the upcoming period due to the increasing demand for personalized and premium packaging for complex drug delivery systems. There is also a high demand for drug-integrated packaging. 3D printing permits the creation of drugs with exact dosages and makes tailored release profiles. This is crucial for personalized medication regimens, particularly for pediatric patients or those with specific medical needs. Pharmaceutical firms can rapidly and cost-effectively prototype and iterate on packaging designs. This agility accelerates the entire drug development process, from formulation to delivery.

Access our exclusive, data-rich dashboard dedicated to the 3D Printed Packaging Market - built specifically for decision-makers, strategists, and industry leaders. The dashboard features comprehensive statistical data, segment-wise market breakdowns, regional performance shares, detailed company profiles, annual updates, and much more. From market sizing to competitive intelligence, this powerful tool is one-stop solution to your gateway.

Access Now: https://www.towardspackaging.com/contact-us

Recent Breakthroughs in the Market

- In November 2024, Stratasys Ltd. partnered with Baralan to enhance cosmetic packaging using PolyJet™ 3D printing technology. The collaboration enables the production of customized, fully decorated end-use parts on glass and plastic containers, supporting personalization and low-volume runs for premium cosmetic brands.

- In April 2024, Harpak-ULMA launched a nationwide 3D-printing service for thermoform tray prototyping, offering customizable designs with intricate features or branding. The service uses SLM and FDM printers with materials like ABS, nylon, PETG, and PLA.

Top 3D Printed Packaging Market Players

- Stratasys Ltd.

- 3D Systems Corporation

- Materialise NV

- EOS GmbH

- Arcam AB

- SLM Solutions Group AG

- Carbon, Inc.

- Desktop Metal, Inc

- Nexa3D

- Protolabs Inc.

- GE Additive

Segments Covered in the Report

By Material Insights

- Plastics

- Paper & Paperboard

- Aluminum

By Technology Insights

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Digital Light Processing (DLP)

- Multi Jet Fusion (MJF)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Binder Jetting

- Laminated Object Manufacturing (LOM)

By End-Use Industry

- Food & Beverage

- Cosmetics

- Pharmaceutical

- Consumer Goods

- Industrial Goods

- Electronics

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/price/5680

Become a Valued Research Partner with Us - Schedule a meeting: https://www.towardspackaging.com/schedule-meeting

Request a Custom Case Study Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Towards Packaging, Your Trusted Research and Consulting Partner, Has Been Featured Across Influential Industry Portals - Explore the Coverage:

- Flexible Packaging Market - PACKNODE

- Is it finally safe to ditch your phone case? I put it to the test

- Battery Brands Charge Forward with Plastic-Free Packaging

- Why Non-corrugated Boxes Are the Future of Packaging

- Ampoules Packaging Market Size Expected to Reach $11.27 Bn by 2034

- Flexible plastic pouches projected to boom over the next decade

- GLOBAL PET FOOD PACKAGING MARKET SET TO DOUBLE BY 2032

- The Skinny on the Skin Packaging Market

- Healthcare Goes Green & Sterile

- The Different Types of Adhesives for Paper Packaging

-

Child-Resistant Packaging: Cannabis and So Much More

Towards Packaging Releases Its Latest Insight - Check It Out:

- Volume-Optimized Corrugated Packaging Systems Market Size & Share

- Plastic Corrugated Sheets Market Drives at 5.34% CAGR (2025-34)

- Corrugated Fanfold Market Driven by 3.85% CAGR (2025-34)

- Shaped Corrugated Packaging Market Drives at 4.9% CAGR (2025-34)

- Old Corrugated Container Market Drives at 4.9% CAGR (2025-34)

- Corrugated Bulk Bin Market Drives at 5.2% CAGR (2025-34)

- Corrugated Wraps Market Drives at 4.80% CAGR (2025-34)

- High Impact Corrugated Boxes Market Drives at 3.04% CAGR (2025-34)

- Corrugated Plastic Tray Market Drives at 5.14% CAGR (2025-34)

- Multi Depth Corrugated Box Market Drives at 5.23% CAGR

- DNA Packaging Systems Market Key Trends, Disruptions & Strategic Imperatives

- Reengineering Packaging Market Strategic Growth, Innovation & Investment Trends

- Aerosol Cans Market Driven by 5.75% CAGR (2025-2034)

- Plastic Container Market Drives at 5.54% CAGR (2025-34)

-

Non-Corrugated Boxes Market Drives at 7.5% CAGR (2025-34)

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.